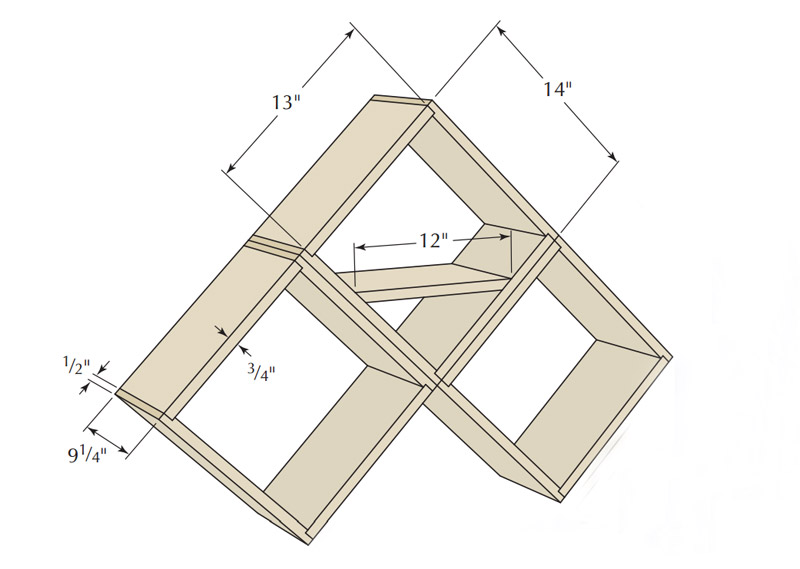

This Bookshelf / Wine Rack will help solve a problem common to evenings spent beside the hearth – whether to drink or read – by gently encouraging both. The shelf can also be reoriented to sit in a standard position, and allows for expansion by building additional modules as you like.

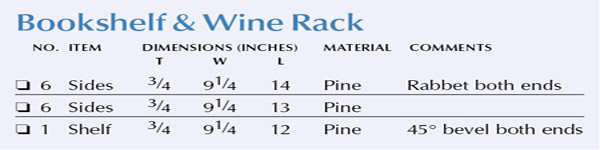

Materials:

Plan:

At the home center, I picked up two 8′ lengths of 1″x10″ yellow pine. Because the boards are cut down to short lengths for the sides of the box modules, there’s no need to fret if the lumber you find has a bit of a bow or twist (a problem common to big-box lumber); imperfections will be worked out during construction.

First, you need to cut the 12 box sides to size. To accommodate the rabbets used to join the sides, you’ll need to cut six 14″ lengths from one board and six 13″ lengths from the other.

I used a miter saw, but a circular saw will work just as well – provided you use a piece of scrap as a fence to guide it. Set aside the extra wood from the ends; this will provide the material needed for the mitered shelf in the middle unit.

Building the Modules

Now that you have the basic component pieces, it’s time to start constructing the individual boxes. Each box is joined with rabbets that are glued together, and then nailed for reinforcement.

Two rabbets are cut into each 14″ length of board – one at each end, and on the same side of course. Cut these using a router with a 3⁄4″ bit set for 1⁄4″ deep. To set up this cut, I first marked the width of the rabbet from the end of the board, and then aligned the router to the line. I marked the edge of the router base, drew a line and clamped down a piece of scrap that acts as a fence. Mark this same distance – from the end of the board to the fence – on the rest of your boards. I used a combination square to be positive the rabbets were reproduced identically.

Rabbets & fences: Set up a fence to keep the router perfectly straight.

When all the rabbets have been cut, it’s time to put the boxes together. Standing two 14″ rabbeted pieces, and two 13″ pieces on their sides, line up the shape of the box and apply a little glue to the joint surfaces.

At this point, it’s helpful to have an extra pair of hands to hold the sides together – children are particularly suited to this task, if you have any lying around. Check the boxes with your combination square before adding a few clamps, and then check for square again. It’s vital that you check twice because the force of the clamps can throw the boxes out of square.

Adjust as necessary, and then leave the glue to dry overnight. The next day, drill pilot holes for 6d nails (four to each rabbet) and tap them in to reinforce the joint.

Make the Shelf

Choose one of your boxes, it doesn’t matter which, to house the horizontal shelf. Grab the leftover piece of pine from earlier and use your square to mark a 45° angle on one end of the board.

A jigsawn bevel: Set your jigsaw’s baseplate to a 45° angle to cut the shelf to size.

You should have about 18″ of board to make the 12″ shelf, so there is no need to measure length yet – just get fairly close to the end.

I considered using the miter saw for this (which would have eliminated the need for marking the angle), but the piece is so small that it would be a scary cut to make. Break out the jigsaw instead.

Set it to 45° and find your fence placement from the line the same way you found the router fence placement. Steady yourself, then make the cut.

To get the correct length, measure 12″ from the outside of the bevel you’ve created – that mark will be your next cut. Make sure that the bevels on both ends slope toward the bottom of the piece before making the second cut.

Installing the shelf in the box may seem a bit tricky. The piece, which fits snugly into exactly the right place with no measurements whatsoever, will want to slide around when you nail it.

To avoid this, clamp the piece of 45° scrap you just cut to the inside of the box. The matching angle will provide all the support you need. Drilling pilot holes into the shelf will make this process even easier – just a few taps and you’ll be in.

Tune-up & Assembly

The flip side to the convenience of big-box lumber is that the boards are seldom perfect. Those slight defects translate into less-than-pristine edge alignment in the joinery, even if your boxes are perfectly square.

No worries – this is what a block plane is made for. Use it to trim the front edges flush. Final assembly of the piece is the easiest part of the entire project. Place the middle box on its side and stack one of its companions on top. Make sure to align the sides so they match: rabbet with rabbet on one, non-rabbet with non-rabbet on the other.

Trim up the edges: Dimensional lumber seldom results in perfect boxes – but a block plane can easily solve the problem.

The continuity won’t stand out as a feature, but discontinuity will. Clamp the boxes together and tweak the alignment as necessary. Drill four countersunk pilot holes about 11⁄2″ from each corner, and install the screws. Flip the whole thing over and attach the third box.

Add a few coats of clear Watco Danish Oil (or the finish of your choice) and this piece is ready hold books. Or wine. But preferably both. The wonderful thing about this piece: If you get sick of it sitting on its corners, flip it over to stand upright. It’s even small enough to hang on a wall. And of course you can always expand it by building more modules.

Leave a Reply