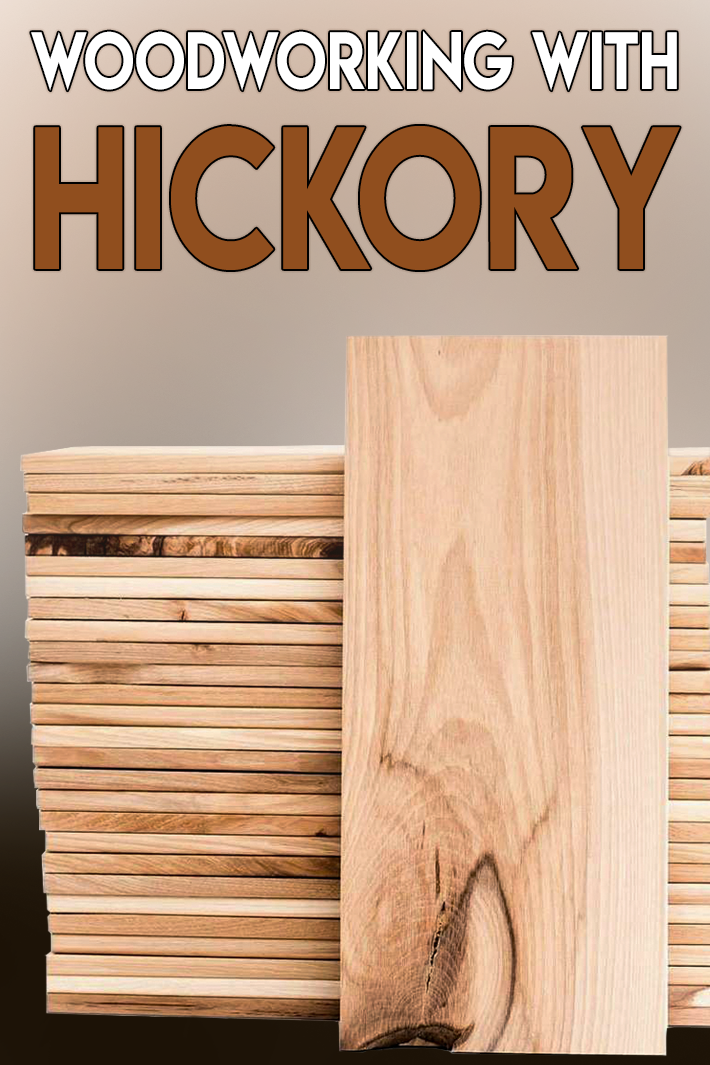

Hickory is a hardwood that is milled from a variety of trees all commonly grouped under one umbrella and sold as hickory. All have very similar characteristics, chiefly among them a combination of hardness and strength that is not found in any other hardwood species. For this reason, hickory is a common choice for use in industrial applications, from shovel and hammer handles to agricultural implements.

The strength of hickory is legendary in American lore. The wood was a choice of covered wagon builders who needed strong wheel spokes. Former United States President Andrew Jackson, often referred to as Stonewall Jackson, was reportedly so tough on his men that they referred to him as “Old Hickory.” Some early car manufacturers, such as the Stearns Steam Engine Company, used it in the frames because of the combination of strength and durability. Babe Ruth was reported to have used a mammoth hickory baseball bat for some of his monstrous home runs.

Even today, some golf club shafts are made out of hickory because of the strength of the shaft. More common uses of this strong material include varieties of hickory flooring.

Hickory trees are prevalent in much of the eastern United States, with some sub-species even found through the southwestern parts of the country and into northern Mexico. Much like mesquite, hickory is a popular hardwood for charcoal and meat smoking, as it gives off a smoke that provides a distinctive flavor to the meat. Many a home or garden center sells bags of hickory chunks for home smokers.

Working with Hickory

As one might imagine, working with such a tough material can take a toll on the blades, bits and knives used to mill the wood. Because it is so hard, it doesn’t always cut cleanly, so keeping your cutting tools sharp is as important when working with hickory as any hardwood. Even with sharp tools, hickory is prone to tear-out, especially when surface planing a board down to a particular thickness or when jointing an edge to make it square to the face of the board or a face to make it as flat as possible. As such, it is imperative when working with hickory that you take very small bites when planing or jointing to avoid gouging the material.

Routing edge profiles can be another task where hickory can be fickle. In addition to making a few passes, taking smaller bites than one might normally take, keep the router moving at a constant speed to avoid burnishing the wood and burning up your bits. Also, as with planing and jointing knives, your router bits must be kept very sharp for effective edge profile routing on hickory.

Even though hickory is notoriously hard, it is particularly well-suited for steam bending when green. This makes it a great choice for making Windsor chairs and other such common pieces that require bent wood. Thoroughly kiln-dried or cured hickory is much more difficult to bend, so use wood that is as freshly-cut as possible for your steam bending applications.

As one might expect with such a tough material, hickory holds mechanical fasteners such as wood screws and nails well, although I would advise pre-drilling pilot holes before installing wood screws to avoid splitting the material. A variety of wood glues seem to hold hickory well, although longer drying times than normal may be necessary.

When it comes to finishing hickory, take care to sand as much as possible with the grain of the wood. Even when using a random orbit sander, try to move with the grain of the wood to avoid scratching. Many hard woods are susceptible to scratching, which can be particularly evident when sanding a hickory turning on a wood lathe. Instead of trying to sand with the lathe on and burnishing the turning with a handful of sawdust, turn off the lathe and sand with the grain of the wood to avoid scratching.

Hickory can be stained or painted equally well, but as with many hardwoods, I recommend use of a pre-stain conditioner to help even out a potentially blotchy wood finish when staining. Use of a wood filler before final sanding can help smooth out any rough patches that are difficult to sand to a glassy finish.

Leave a Reply