Butt Joint is the most basic method for connecting two pieces of wood, and while it isn’t the strongest of joints, it is very useful in some situations. This type of joint is often used in wall framing on construction sites. You can learn how to make a butt joint by using proper technique to ensure that your butt joints are as strong as possible.

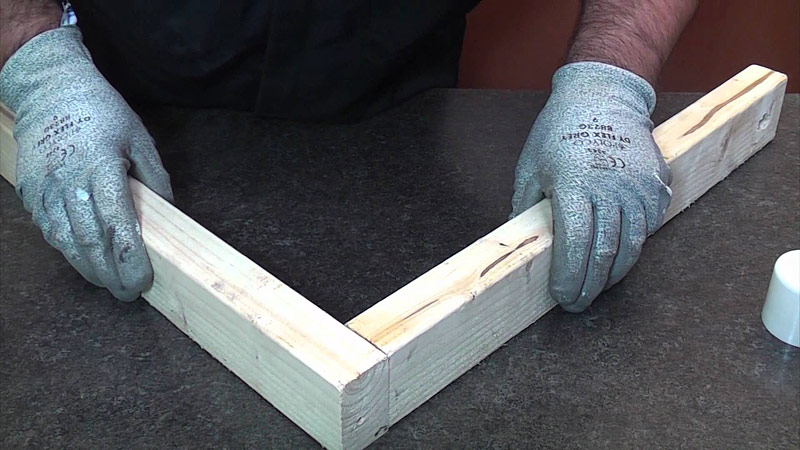

As shown in the picture, a butt joint is where one piece of stock is butted against another and affixed with glue. The joint is usually strengthened by screws or nails.

Square Cuts are Key:

The key to a quality butt joint is to make certain that the ends of the two boards are cut as square as possible. This is easiest using a miter saw, although quality results can be obtained by using a circular saw and a Layout Square, provided that angle of the blade of the circular saw is set to zero-degrees.

Glue Provides the Strength:

The strength of a butt joint comes from the glue in the joint. However, there are two problems with using glue as the only means of holding the connection.

First, when glue is applied to the end grain of a board, it tends to soak into the stock far more than glue applied to the side of the grain. The end grain is the most porous part of the wood, so you may need to apply a bit more glue than normal.

Second, the glue will not provide much in the way of lateral strength. As such, it is advisable to use some screws or nails to strengthen the joint.

If using hardwood for your project, be certain to pre-drill the pilot holes before inserting screws into the joint, or you’ll split the stock and have a bigger problem on your hand than a weak butt joint.

Leave a Reply