Pine is among the most common species of softwood available in home centers today. When woodworking with pine, there are many species from which to choose, but they all tend to get lumped in together and are commonly regarded as being somewhat utilitarian in nature (good only for building shelving, framing or other projects not typically associated with fine woodworking). While pine has its limitations, this is a rather unfortunate outlook.

Stable pine, particularly that of a more antique nature, is among the most revered of wood stock and can be more stable than popular hardwoods such as maple or cherry.

In the US, the two most commonly available varieties of pine are Eastern white and yellow pine. Yellow pine is a bit harder than Eastern white pine and can be a bit more difficult to cut. However, when used properly, either can give fantastic results.

Most of the limitations fall into two categories. For one thing, pine tends to scratch or dent easily. Second, pine from the lumber yard is typically sold a bit wetter than optimum. This can lead to movement in the wood as it acclimates to the local environment. Fortunately, both of these limitations can be dealt with rather easily.

Dealing with Moist Pine

Pine (and it’s cousins, Spruce and Fir, which make up the SPF triumvirate type of wood used to make most construction materials) is often kiln-dried, but rarely is as dry as optimally needed for fine woodworking.

As such, when this construction material reaches a job site, it is used as quickly as possible to avoid twists, bows and cups. The old construction axiom of “use it the day you get it” really can’t apply to fine woodworking applications of pine.

A better approach would be to pick through the stock at the home center for the best pieces you can find, then stack them carefully at your shop lumber storage location for a few months and allow them to acclimatize to the local environment.

Look for clean stock with as few knots as possible, preferably somewhat resembling quarter-sawn (with the grain lines perpendicular to the longer axis in the end grain). By allowing a stack of this wood to reach a state of equilibrium with the environment, aided by the weight of the other boards in the stack, you should have some relatively stable pine with which to work.

Of course, one should always be on the lookout for antique pine timbers. There is little more satisfying in woodworking than obtaining some 100-year-old antique long-leaf pine from an old abandoned barn or house and turning that recycled lumber into works of art.

After your stock has had a chance to reach a state of equilibrium with the environment, you may still have some cupping or warping issues with which to deal. Fortunately, this is why we have surface planers and jointers.

Dealing with Pitch

Pine has a reputation for leaving a lot of pitch (or pine tar) on woodworking blades. While properly curing the pine will help immensely in dealing with excessive pitch, there are still a number of tips that can be used for removing pitch buildup from blades. For basic cleaning, I like to use a quality all-purpose cleaner.

My favorite is about three tablespoons of a natural laundry soap (like the liquid laundry soap from Cal-Ben Soap) mixed in a quart spray bottle filled with water. This does a great job of removing pitch from blades and bits, particularly before the pitch buildup has gotten too heavy.

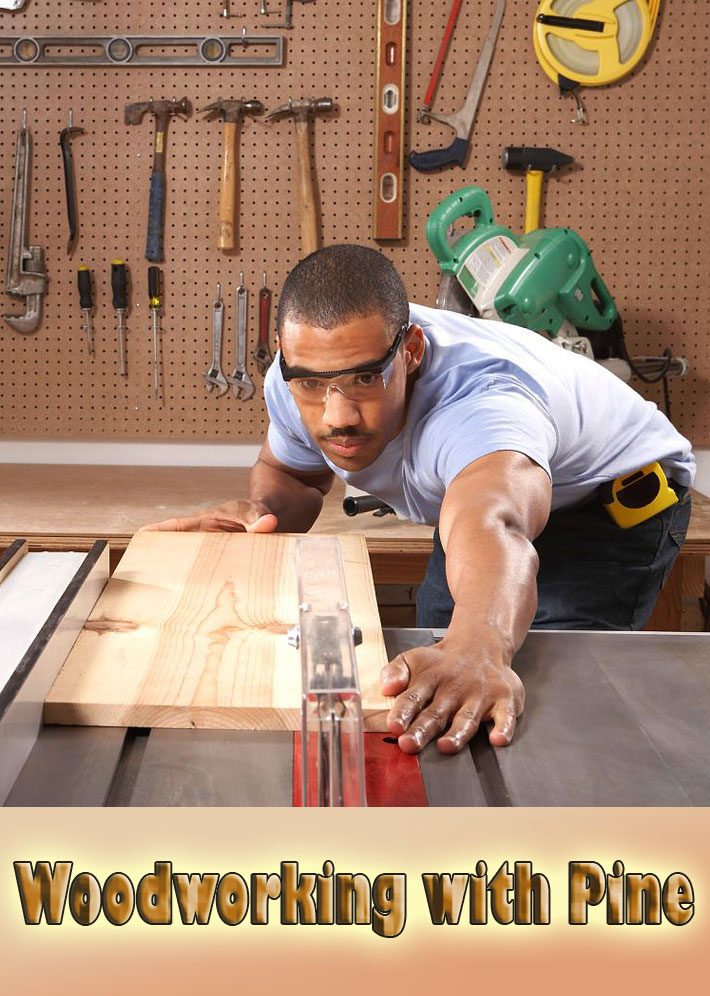

Keep Your Tools Sharp

In addition to keeping your blades and bits as pitch-free as possible, you should also make certain that your blades and bits are quite sharp when working with pine. Because of the relatively soft nature of the wood, a less than very sharp blade or bit will tend to crush the wood instead of cutting cleanly. This will lead to a lot of chipping and splintering in the cuts, and less than optimum results.

Scratches and Dents

As mentioned earlier, fresh pine also is relatively easy to dent and scratch.

To address this when building with pine, I’m careful to keep a clean work surface, removing any loose wood chips, tools or fasteners from the work table. When working on the shop floor, a cut-up cardboard box will protect the surface of the wood from imperfections in the floor quite nicely.

Should a scratch occur, you should be able to remove it relatively easily with a random orbital sander.

Dents can be a little more tricky to address. Old-school carpenters commonly use a generous dab of saliva to address a hammer dent in pine. (That’s a nice way to say that they spit on the dent.) The moisture tends to fill into the crushed stock, and 20-30 minutes later, the dent is barely noticeable.

While I’m certainly not advocating a similar procedure in the wood shop on a fine woodworking project, the principle is similar. A damp cloth positioned over the spot covered with a hot iron for a few seconds will often remove the blemish. The steam works its way into the fibers and camouflages the dent.

Finishing Pine

When finishing pine, be certain that the wood has had ample time to acclimatize to the local environment. If you built the project before allowing the wood to reach a state of equilibrium, you’d be wise to allot that time before finishing. Without waiting for the wood to equalize with the surrounding environment, your finish will not be as durable as desired.

For painted projects, be sure to caulk all joints and fill all nail/screw holes appropriately. Then, after a final sanding, use a few coats of a quality primer before applying the desired layers of top coat paint.

For stained projects on pine, I strongly advocate the use of a pre-stain conditioner. This conditioner will even out the color of the stain across the project, providing a much more consistent color than a project not using such conditioner.

After applying the conditioner as recommended by the manufacturer, you can apply the stain and protective finish (such as polyurethane) of your choice.

Leave a Reply